Contents of factory 5s management system

2019-01-08

Nowadays, many defective products, delivery delays, serious waste, equipment failures and inadequate safety management exist in the field management of factories, leading to frequent accidents on the production site.Not only affect production, damage reputation, serious will lead to the closure of the enterprise bankruptcy, the person in charge even face legal punishment!Thus it can be seen that the field management is particularly important for the production enterprises and is the cornerstone of the field management.However, 5s management originated in Japan has been implemented and applied by many enterprises as one of the basic field management of enterprises and achieved good results.How does the factory implement 5s management?Let me introduce the 5s management system of the factory.

Clear up

1. Responsible for 5S management in the workshop, responsible for the organization, implementation and implementation of 5S.According to the requirements of 5S arrangement and rectification, and in combination with the actual situation of the workshop, the storage location and storage quantity limit of articles on site shall be determined, and shall be firmly implemented.If there is any change in the future, it shall be approved by the workshop leading group, and the fixed mark shall be changed in time.

2. Before going to work, the workshop staff shall timely clear the passageway in the responsibility area of the post (useful articles shall not be piled up for a long time, and garbage shall be cleared in time), and the articles shall not be placed beyond the passageway to ensure the passageway smooth and tidy.

3. Equipment shall be kept clean and materials shall be stacked neatly.

4. Recently used articles are put on shelves, and often unused articles are stored in warehouses.

5.Work table items are neatly arranged for easy access.All processes shall be labeled in accordance with the location, and objects, including tools, semi-finished products, raw materials and reports, shall be placed in order.

The consolidation

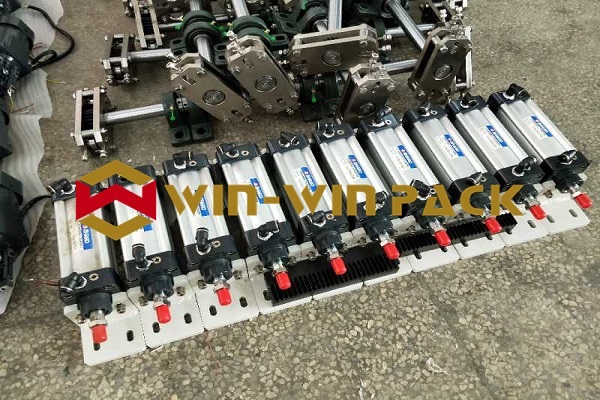

1. The equipment, machine and instrument are maintained in a neat, clean and optimal state.

2. The tools are maintained, positioned and placed, and visual management is adopted.According to the actual situation of the workshop, set the tools, determine the storage location and storage capacity limit of field items, and resolutely implement.If there is any change in the future, it shall be approved by the workshop leading group, and the fixed mark shall be changed in time.

3. Products: good products and defective products shall not be mixed together, and shall be kept and positioned clearly.

4. All public passageways, corridors and stairs should be kept clean and tidy. Walls, ceilings, Windows, lamps, doors and Windows should be free from cobwebs and dust.

5. Keep the management board tidy.

6. Clean up garbage and waste products in the workshop.(each department shall be dealt with according to the division regulations)

Cleaning

1. The public passage should keep the ground clean and bright.

2. Items in the work place shall be placed in order.

3. Keep Windows, walls and floors clean and bright;Waste or old equipment should be disposed of in time and not piled up everywhere.

4. Equipment, tools, instruments in the use of anti-cleaning measures, and clean at any time.

5. Workshop staff shall clean and divide the area in time to ensure cleanliness and tidiness.