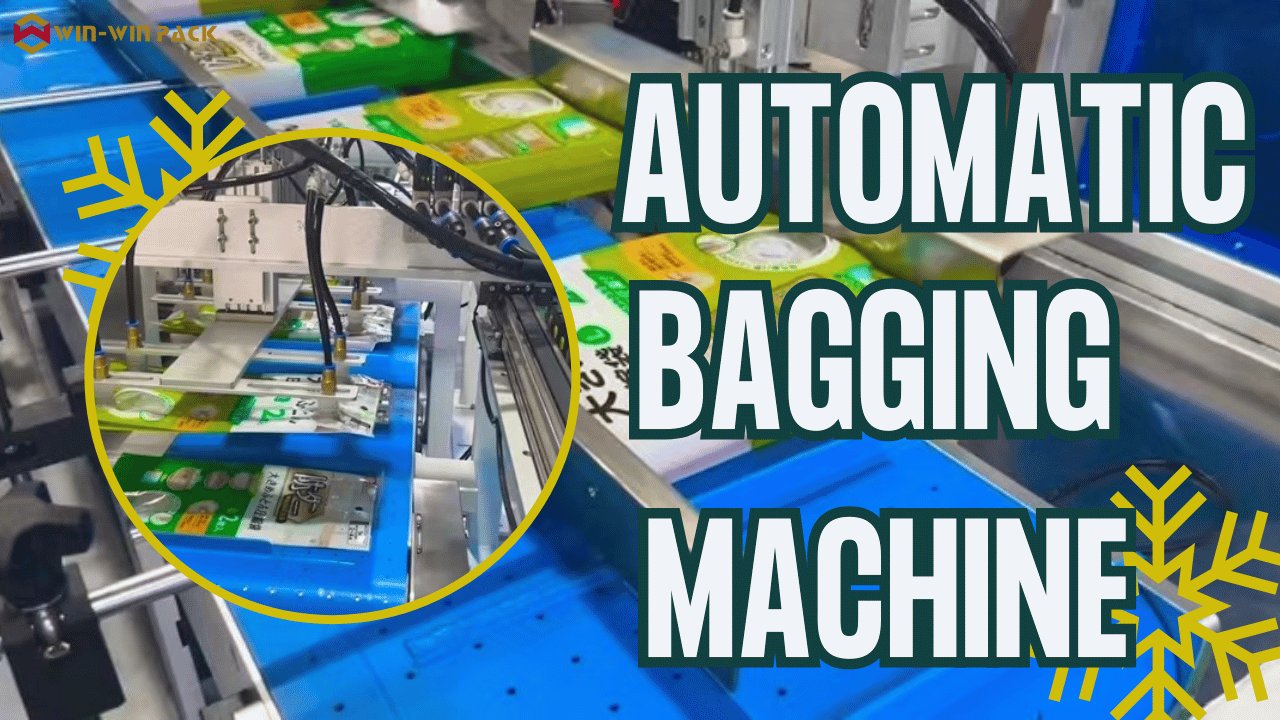

Automatic Bagging Machine: Revolutionizing Packaging Efficiency

2024-12-23

In the fast-paced world of modern manufacturing and logistics, the efficiency of packaging systems plays a crucial role in meeting market demands. Among the numerous innovations in this domain, the automatic bagging machine has emerged as a game-changer, transforming how products are packed and delivered. This article explores the key features, benefits, and applications of automatic bagging machines, highlighting their importance in today’s industrial landscape.

An automatic bagging machine is a sophisticated piece of equipment designed to streamline the process of filling and sealing bags. Using advanced technology, these machines automate tasks that traditionally required manual labor, including weighing, loading, sealing, and labeling. They cater to a wide range of industries, such as food and beverage, pharmaceuticals, agriculture, and retail.

Equipped with advanced sensors and control systems, these machines ensure accurate bag filling, reducing waste and enhancing product quality.

They can accommodate various bag types, sizes, and materials, making them suitable for diverse products, from granular substances to bulky items.

Modern machines often feature touchscreens and intuitive software for easy operation and troubleshooting.

Benefits of Using Automatic Bagging Machines

Increased Efficiency: Automation reduces the time and labor required for packaging, leading to faster production cycles and quicker turnaround times.

By minimizing manual intervention, companies can save on labor costs while achieving consistent packaging quality.