+86075584509986

+86075584509986

1.Efficient packaging

With an average of 14 packs per minute, the packaging efficiency is about three times that of the manual.

2.The packaging is firm and beautiful

Compared with the manual packaging, our machine is used to make the packaging more firm and beautiful, which helps to enhance the brand value.

3.More choice of consumables

A variety of films (PVC/PE) are available for cost savings; some brands of similar equipment can only use the specified film.

In addition, it can be packaged with or without trays, and is suitable for trays of various shapes (such as round, hexagon, etc.)

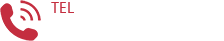

4.High quality material

The whole machine adopts stainless steel to adapt to the corrosive environment such as high humidity; the similar equipment of other brands only partially or completely does not use stainless steel, and is easily corroded under harsh environment.

5.Comfortable for use

The operation interface is simple in design and fast in response; it adopts special mute processing, which is less noisy and more comfortable to use than other similar devices.

6.Exquisite workmanship

Overall welding processing, equipment stability is better than similar equipment of other brands.

1.Efficient packaging

With an average of 15 packs per minute, the packaging efficiency is about three times that of the manual.

2. Multifunctional

It combines the functions of automatic packaging, weighing and printing labels to save costs.

3. The packaging is firm and beautiful

Compared with the manual packaging, the machine are used to make the packaging more firm and beautiful, which helps to enhance the brand value.

4. More choice of consumables

A variety of films (PVC/PE) are available for cost savings; some brands of similar equipment can only use the specified film.

In addition, it can be packaged with or without trays, and is suitable for trays of various shapes (such as round, hexagon, etc.)

1.Efficient packaging

The packaging speed is up to 25 packages per minute, and the packaging efficiency is about 5 times of that of human packs.

2.Packaging effect

The machine adopts film pressing design, which makes the packaging stronger and more beautiful, it helps to enhance the brand value.

3.The machine is reliable and durable.

The machine adopts high-definition touch control, which makes the response faster. And choose Schneider Electric appliances.

4.Reduce manual action, simple and comfortable operation

The machine needs to place products at the front of machine, and the design of human-machine interface is simple, which makes the operation more convenient and easier.

5.More choice of consumables

A variety of films (PVC/PE) are available for cost savings.

6.High quality material

The whole machine adopts stainless steel to adapt to the corrosive environment such as high humidity; the similar equipment of other brands only partially or completely does not use stainless steel, and is easily corroded under harsh environment.

7.Comfortable

The operation interface is simple in design and fast in response; it adopts special mute processing, which is less noisy and more comfortable to use than other similar devices.

8.The machine can pack large volume products.

The machine can pack the whole chicken/the whole fish and the big box of fruit.

9.Establish an integrated packaging line

It can integrate printing and labeling machine, disc material handling machine, metal inspection machine and other machines, and combine together as a full-automatic and efficient packaging line.

10.Intimate service

The machine is independently developed and produced by WIN-WIN PACK, with the top technology in China, which can respond quickly. We provide 24-hour online service, If necessary, we can send someone to provide on-site service.

1.Double servo control, the bag length is set and cut immediately, no need to adjust air, one step in place, save time and save film.

2.Color touch screen control, convenient and fast parameter setting, can store 100 kinds of packaging parameters.

3.Fault self-diagnosis function, fault display at a glance.

4.High sensitivity photoelectric eye color mark tracking, mathematical input sealing and cutting position, make sealing and cutting position more accurate.

5.Temperature independent PID control, better suited to a variety of packaging materials.

6.Positioning stop function, no sticking knife, no waste of coating.

7.the transmission system is simple, work more reliable, more convenient maintenance.

8.Anti-cutting material function, the edge of the knife senses that the product is sent out automatically.Do not cut to product, protect product and knife holder.

9.No packaging film, automatic stop.

10. Automatic sensing products to packaging, there is product paper and cutting knife action, no product paper and cutting knife action, no waste of membrane.

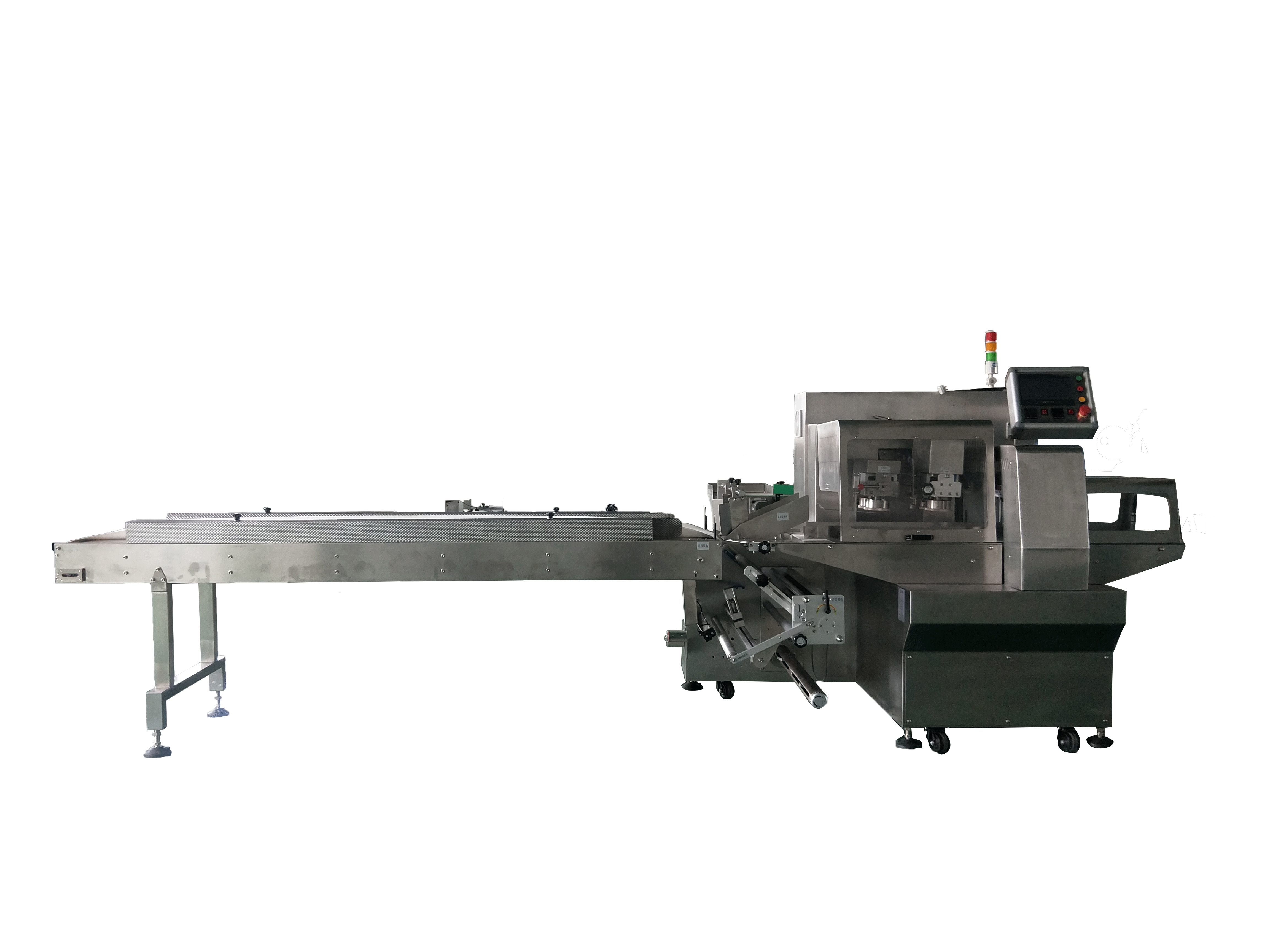

1. Full servo control, the bag length is set and cut immediately, no need to adjust the idling, one step is in place, saving time and film.

2. Color touch screen control, convenient and quick parameter setting.

3. With parameter storage function, it can store 40 kinds of packaging menus, and it is convenient and quick to change products. Fault self-diagnosis function, fault display is clear at a glance.

4. High-sensitivity photoelectric eye color mark tracking, digital input of the sealing and cutting position, so that the sealing and cutting position is more accurate.

5. Independent PID control of temperature, better suitable for various packaging materials.

6. Positioned stop function, no sticking to the knife, no wasting of film.

7. The transmission system is simple, the work is more reliable, and the maintenance is more convenient.

8. The product is automatically reversed when it is cut, and it is easy to operate directly after restarting. When the machine is abnormal, it protects the tool holder and is safer at the same time.

9. There is no packaging film, automatic shutdown, replacing the packaging film not only saves time, but also saves the packaging film.

10. Anti-aircraft bag function, there is no product packaging film and the cutter does not move, saving packaging film.

11. Fully automatic packaging does not require manual material placement, just pour the fruit into the hopper of the packaging machine, and the machine will automatically lift the fruit into the packaging machine to complete the packaging.

12. The whole fruit line is conveyed by nylon rollers, brush rollers, and plastic push fingers to prevent the fruit from being scratched and broken.